Promoting the Green Procurement of Raw Materials

Based on its environmental policy, the Nichiban Group pursues the manufacture of products that are safe, healthy, and environmentally friendly throughout their entire life cycle (development, manufacturing, distribution, use, and disposal). As part of these efforts, we promote the procurement of raw materials and parts with low environmental impact and the appropriate management of chemical substances. In proactively promoting these initiatives, we publish the Nichiban Group Green Procurement Guidelines, which summarize our basic approach and requests for suppliers, while promoting the reduction of environmental impacts throughout the supply chain.

Disclosure of SDS, RoHS, and Other Information on Major Products

Nichiban strives to manage the chemical substances contained in its products based on the Nichiban Group Green Procurement Guidelines. As laws and regulations concerning environmentally hazardous substances become increasingly stringent each year both in Japan and overseas, inquiries from customers regarding the chemical substances contained in our products are also on the rise. We maintain a close watch on the revision of related laws and regulations, and gather information to provide prompt responses to customer inquiries. For major products that receive frequent inquires, we make safety data sheets (SDS), RoHS directives, and other information available on our website to ensure the prompt provision of information.

Act on the Regulation of Manufacture and Evaluation of Chemical Substances in Japan

In order to prevent environmental pollution by chemical substances, Nichiban manages operations in accordance with laws and regulations, including the reporting of new chemical substance production and production volumes.

Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof in Japan

The Nichiban Group recovers most organic solvents discharged during the coating process and reuses them repeatedly. We also manage the small amount of emissions not fully recovered, which is reported appropriately. Further, we strive to reduce emissions by converting to solvent-free production methods.

Efforts to Reduce and Eliminate Solvent Usage

The Nichiban Group is continuously working to reduce solvent usage by increasing productivity and changing production conditions. At the Tape Anjo Factory, we have introduced a hot melt coater that uses heat to melt glue for the production of adhesive tape. We are engaged in the research and development of new production methods to further eliminate the use of solvents while promoting their application to new and existing products.

Water Pollution Prevention Act in Japan

Although not subject to this regulation, we voluntarily measure and monitor wastewater discharged from our factories.

Air Pollution Control Act in Japan

We comply with emission standards for volatile organic solvents emitted when drying adhesives. We also voluntarily measure and monitor dust, nitrogen oxides (NOx), and other emissions at facilities that are not regulated, and appropriately report specified dust.

Hazardous Materials Handling and Management

Workers are licensed as hazardous material handlers and are trained in-house to handle hazardous materials properly. Temperature control and static electricity countermeasures are implemented to ensure the proper storage and use of hazardous materials.

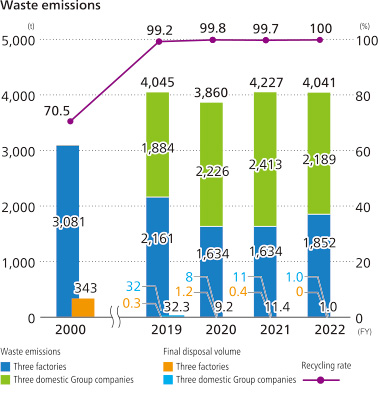

Waste Management

In compliance with laws and regulations, Nichiban outsources waste treatment to subcontractors in accordance with the type of waste. We separate waste for material and chemical recycling, and conduct thermal recycling for waste that is difficult to recycle for reuse as raw materials. Nichiban has achieved zero emissions since 2012.

Reducing Waste through the Effective Use of Raw Materials

Rather than using disposable consumables in manufacturing processes, we attempt to reduce waste by repeatedly reusing materials to the extent that they do not pose any quality issues. We also consult with manufacturers regarding packaging materials when purchasing raw materials and effectively exploit resources by utilizing returnable rather than single use packaging.

Act on the Recycling of Containers and Packaging in Japan

In accordance with the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging, which mandates the recycling of containers and packaging waste generated by households, the Nichiban Group pays a reprocessing consignment fee to the Japan Containers and Packaging Recycling Association for appropriate disposal.

Plastic Resource Circulation Act in Japan

As a manufacturer, Nichiban strives to design products in accordance with design guidelines for products that use plastic. Further, we set a target for reducing the amount of industrial waste generated from plastic products in fiscal 2025 by 5% (per unit produced) compared to fiscal 2021, and increasing material and chemical recycling rates to at least 7% of the total in fiscal 2025, among other initiatives aimed at curbing emissions and recycling waste. Over 99% of waste that is difficult to recycle by material or chemical means is recycled through initiatives involving thermochemical substances.

| Fiscal 2022 industrial waste emissions from products that use plastic | 3,226t |

|---|