We are working to reduce the environmental impact of factory

At Nichiban, we are committed to using natural materials and delivering products that are friendly to people and the environment.

Factory and Office Initiatives

The Nichiban Group aims to reduce CO2 emissions and power consumption in order to reduce our environmental impact. Thorough control of air conditioning and LED lighting fixtures used in various places in offices and factories are being progressively adopted.

At the Saitama Factory, demand control is introduced into the air conditioners at the production site, and the peak power is cut according to the power consumption of the factry.

At the Technology Center, we have installed motion sensors in places where lighting is not required at all times, in conjunction with the use of LED lighting equipment, and are working to reduce power consumption so as to avoid wasting power due to forgetting to switch the lights off.

Logistics Initiatives

The Nichiban Group requests that transport companies outsource logistics to proactively engage in environmental conservation activities, such as reducing CO2 emissions. In addition, we are promoting the switchover of sales vehicles to hybrid vehicles, and posting posters to promote eco-driving among all employees to raise awareness.

We will continue to consider modal shifts such as railroad use to reduce CO2 emissions.

- *Modal shift

Changing the method of freight transportation from trucks to railways and ships with low environmental impact.

Nichiban Selected as an Excellent Energy-saving Business

Nichiban has been selected as an excellent energy-saving business in the Japanese Ministry of Economy, Trade and Industry's Energy Conservation Act business classification evaluation system since fiscal 2021, maintaining an S-class rating since the classification system was launched.

Nichiban Medical received an A-class rating in fiscal 2021. Going forward, the Nichiban Group will redouble efforts to save energy.

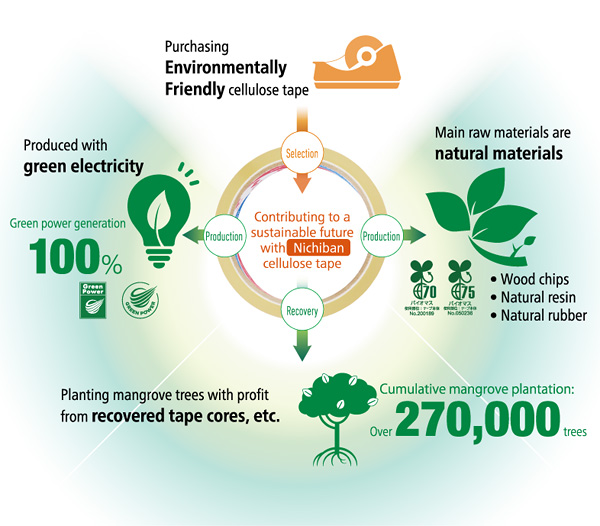

Contributing to the SDGs with Cellulose Tape

Cellophane, the base material of cellulose tape, is made from wood pulp, the adhesive is made from natural rubber and resin, and the tape core is made of recycled paper. Since the main raw materials are natural, renewable materials, cellulose tape is a product that can contribute to reducing environmental impacts (certified as a Biomass Mark product by the Japan Organics Recycling Association).

Nichiban will contribute to the SDGs through small actions such as replacing plastic tape, which is made mainly from fossil resources, with cellulose tape.

Cellulose Tape Eco-Circle

For more than 70 years, Nichiban has manufactured plant-derived cellulose tape as an environmentally friendly, recycling-oriented ecological product, with the health and safety of our customers in mind. We are committed to reducing CO2 emissions through an eco-circle centered on cellulose tape and contributing to a carbon-neutral and sustainable future together alongside our customers.

Nichiban Tape Core ECO Project

Since 2010, we have conducted the Nichiban Tape Core ECO Project to recycle the tape cores used for adhesive tape rolls. During the 13th round of this project (September 1—December 27, 2022), 794 organizations from schools, companies, hospitals, and other organizations and 348 individuals participated, with 523,200 tape cores (weighing 7,160 kg) collected.

The cumulative total number of tape cores collected since the project began has reached more than 5,290,000 (approximately 67 tons).

Nichiban also endorses Paralym Art®, an activity supporting the artistic endeavors of people with disabilities. We have used the work of artists with disabilities for Nichiban Tape Core ECO Project posters, certificates of appreciation, and flower seed designs.

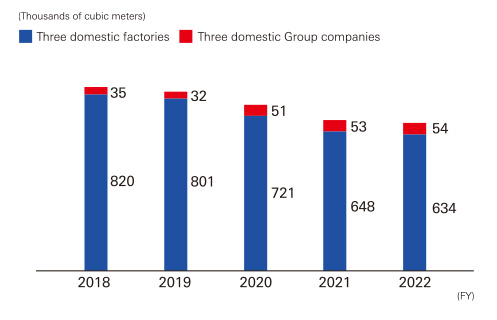

Effective use of water

While securing water resources is an important issue around the world, the Nichiban Group is also working to reduce and use water efficiently. To date, we have promoted effective use of water, such as by circulating cooling water, and our water usage in FY2022 was 688,000 m3 We will continue to reduce water consumption.