The general properties of adhesive tapes are representative performance indicators.

Please use them as a reference when selecting a product based on your intended use and conditions.

- *

The values are based on the International System of Units (SI) and measured according to the JIS Z 0237 standard for adhesive tape testing.

- *

The characteristic values listed are average measured values, not guaranteed values.

Adhesive Tape Composition

Base Material

Also known as the backing, this is the base of the tape. Common backing materials include cellophane,

washi (*Japanese Rice Paper), kraft paper, stapled fiber cloth, and polypropylene film.

Pressure Sensitive Adhesive (PSA)

| Material | Features |

|---|---|

| Rubber | Excellent low-temperature properties and tackiness. |

| Acrylic | Excellent weather and chemical resistance. |

| Silicone | Excellent heat resistance. Excellent adhesion to silicone-coated release liners. |

Solvent-free Adhesive

It is an adhesive that has been dissolved without the use of organic solvents. There are two primary manufacturing methods:

- Hot melt

- A method where the adhesive components are melted with heat.

- Emulsion

- A method where the adhesive components are dispersed in water.

Thickness

Unit : mm

Total thickness of the tape (base material + adhesive)

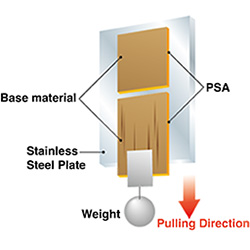

Peel Strength

Unit : N/10mm

This represents the force required to peel the tape from a stainless steel plate at a 180° or vertical angle.

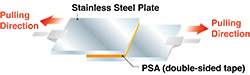

Shear Adhesion

Unit : N/cm2

This is a measurement method for double-sided tape. It represents the force required to peel the tape from between two stainless steel plates when pulled horizontally. A higher value indicates the ability to hold heavier objects.

Tensile Strength

Unit : N/10mm

This is the force required to break the tape when pulled lengthwise. A higher value indicates a stronger tape that can withstand heavier loads.

Autohesion

Unit : N/10mm

This represents the force required to peel the tape from itself when the adhesive sides are stuck together. A higher value indicates better holding power.

Elongation

Unit : %

This represents the percentage the tape stretches before breaking when pulled lengthwise. A higher value indicates greater flexibility, allowing the tape to conform to uneven or curved surfaces.

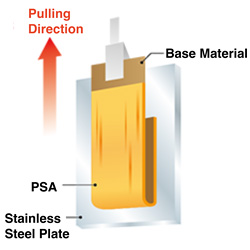

Holding Power

Unit : mm

This represents the adhesive's resistance to slipping. A smaller value indicates better holding power.